An interview with Dr. Anja Laqua, QHSE & Product Stewardship

Sustainability, product safety and environmental protection are important goals in industry. Numerous laws and guidelines are designed to protect consumers, employees and the environment. These requirements can vary greatly from country to country. This poses a challenge for companies, especially in product development, because in order to bring a new product to market, it must meet the local requirements of all markets in which it is sold. Kuraray, one of the world’s leading specialty chemicals manufacturers, supports users of PVB materials of its Mowital® brand, for example, with well-founded information and expertise. In an interview on the QHSE & Product Stewardship (Quality, Health, Safety, Environment & Product Stewardship)focus of specialty chemicals manufacturers, Dr. Anja Laqua discusses why there must be a rethink on sustainability and how customers benefit from working with Kuraray when the environment and product safety are concerned.

Dr. Laqua, sustainability is increasingly becoming a core issue for industry. What challenges do you see in this regard?

Dr. Anja Laqua: Awareness of sustainability and health has increased enormously in recent years. Consumers are right to demand that the products they buy are sustainable and environmentally friendly. Many industrial companies are working to develop products that meet these requirements. An integral, sustainable approach, however, requires another important point.

Which one is that?

Dr. Anja Laqua: Dialogue! Environmental and occupational safety issues often cannot be solved within a single company. There is a need for an exchange of ideas between suppliers, customers and politicians – for example on the use of different plastics for certain applications or on waste and disposal and, of course, on the legal framework conditions. At Kuraray, we are constantly working to promote and stimulate this dialogue.

How do we do that?

Dr. Anja Laqua: Above all, we offer users of our plastic materials technical know-how on compliance issues, from basics such as good manufacturing practice (GMP) regulations to the EU chemicals regulation REACH. Many of our customers also have very specific questions about their applications. The PVB materials of our Mowital® brand are used, for example, in printing inks for food packaging. Depending on the market in which the packaged products are sold, there are very different regulations and requirements – such as the Swiss Printing Ink Ordinance or corresponding specifications in the EU and the USA. Of course, it is always important to keep up to date, because the legal situation changes regularly.

This sounds very complex. How do you help your customers meet these requirements?

Dr. Anja Laqua: The QHSE & Product Stewardship team at Kuraray brings together experts from a variety of disciplines, including environment, health and product safety. Our specialists compile information for users of Mowital® in the form of statements, certificates and regulatory brochures. This provides customers with answers to almost all compliance-relevant questions, which is unique on the market.

To what extent is this service special?

Dr. Anja Laqua: I have to explain this briefly. For Kuraray, as one of the world’s leading specialty chemicals manufacturers, it is particularly important that our customers can rely on our statements. The answers to compliance-relevant questions that users receive are therefore well thought out and very precisely checked and weighed, both in terms of content and technical aspects. This is based on extensive research, which of course takes a lot of work and time. Only a few manufacturers offer this in this form, but this is the only way we can give our customers reliable information.

With the information you provide the basis for customers to develop new products, among other things.

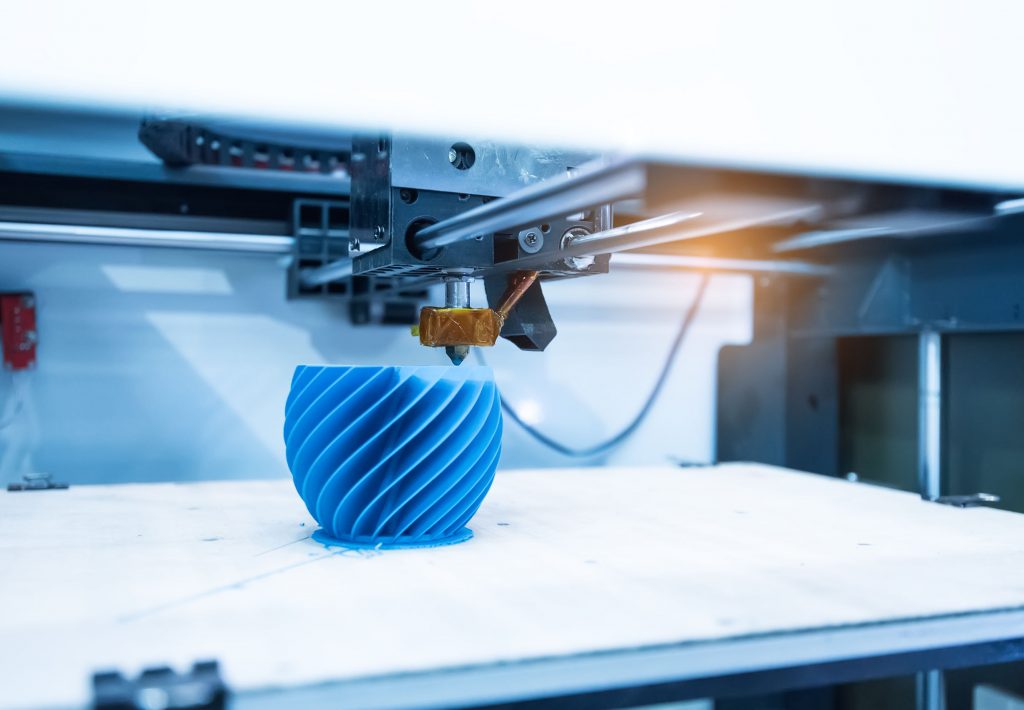

Dr. Anja Laqua: Exactly! In the Mowital sector, 3D printing is currently a trend topic, for which we are, for example, examining the corresponding possible applications for interested parties who produce 3D printing filaments. It can also happen that we advise a customer against using our material for an application because we come to the conclusion that our material does not cover all legal requirements for the application.

What would be an example?

Dr. Anja Laqua: Our PVB materials have specific properties with which they could bring advantages for certain applications in the pharmaceutical industry. However, the plastic is not positively listed in this area. In such cases, unfortunately, we have to say: Good idea, but legally this is not possible with our material. On the market this is not always formulated as clearly as with Kuraray. For us, security, whether legal or physical, always takes precedence. Our customers can rely on this.

In addition to applications for customers, Kuraray also works on many topics in the field of QHSE & Product Stewardship …

Dr. Anja Laqua: That’s right! Kuraray is especially concerned about the safety of its own employees. The topic is firmly anchored in our corporate culture and is lived and promoted in the KURASAFE safety program of Kuraray Europe GmbH and other such programs. We are also constantly working to optimize our processes and, for example, to reduce our CO2emissions and avoid waste. At Kuraray, three teams around the world deal with very different sustainability issues. For example, one aim is to promote the development of new environmentally friendly products.

Such as biopolymer plantic, which is mainly made from corn starch?

Dr. Anja Laqua: Exactly. Another example is the bioelastomer SEPTON™ Bio, a TPE raw material made from sugar cane-based organic farnesene. Our colleagues in research and development are constantly working on new product solutions. Sustainable materials that are biodegradable, compostable or recyclable are becoming increasingly important. In the area of ESHA & Regulatory Affairs, we provide the legal information with which our customers can use the innovative materials in their applications.

How will QHSE & Product Stewardship change in the coming years?

Dr. Anja Laqua: It is becoming apparent that the requirements that legislators place on chemical substances and materials will continue to increase in the future. This is an important reaction to issues that are currently being discussed extensively in society.

For example, avoiding plastic packaging?

Dr. Anja Laqua: Yes. Or issues such as the CO2footprint of products and the reduction of microplastics in the environment. At Kuraray, we are well prepared for this because, with our high level of development expertise, we provide appropriate materials and actively assist users in developing products that meet the higher requirements. At the same time, in the future we will focus even more on how we can inform our customers in a comprehensible way and how we can help them for example to meet stricter emissions limits. Our customers can also rely on our know-how in the future.

Thank you very much for the interview!