Kuraray measures tracking resistance of 925 Volts on Genestar™ PA9T

Electromobility has a key role in holding back climate change. Insulating materials with extremely high tracking resistance are required for the development of high-performance electric vehicles. The CTI index has become established in the industry for measuring insulating strength. One problem is that so far is this standardized measuring method could only be used to determine the tracking resistance of insulating materials at up to 600 Volts (V). For many applications such as electromobility that is far too low. To measure tracking resistance on the surface of its high-performance polyamide Genestar™ PA9T, Kuraray, one of the world’s leading speciality chemicals producers, which has its European headquarters in Hattersheim, Germany, adapted the method to allow testing of materials at voltages of up to 1,000 V for the first time. In these tests, Genestar™ exhibited excellent tracking resistance at up to 925 V, so the material can be used to produce smaller, lighter weight connectors for high-voltage applications.

The CTI index no longer meets the demands made, for example, by the automotive industry. With our tests, we want to inject impetus into the industry.

Andreas Weinmann, Business Development Manager for Genestar™ at Kuaray

“Genestar™ PA9T has excellent electrical and mechanical properties, for example very good heat resistance and dimensional stability. Therefore, our polyamide is already the material of choice for many applications in the electronics and automotive sectors, for instance for high-quality SMT connectors,” says Andreas Weinmann, Business Development Manager for Genestar™ at Kuraray. “Our latest test results confirm that tracking resistance on the surface of this material is well above the level that can be measured using the CTI index.” The CTI index shows the highest voltage at which the test specimen does not generate a current on a damp surface. At present, the maximum voltage used in this method is 600 V. For comparison: engines and batteries in modern electric vehicles often use voltages of up to 800 V. Andreas Weinmann: “To test the limits of Genestar™PA9T, our research team looked for a way of determining tracking resistance above this level. That was the basis for the test setup.”

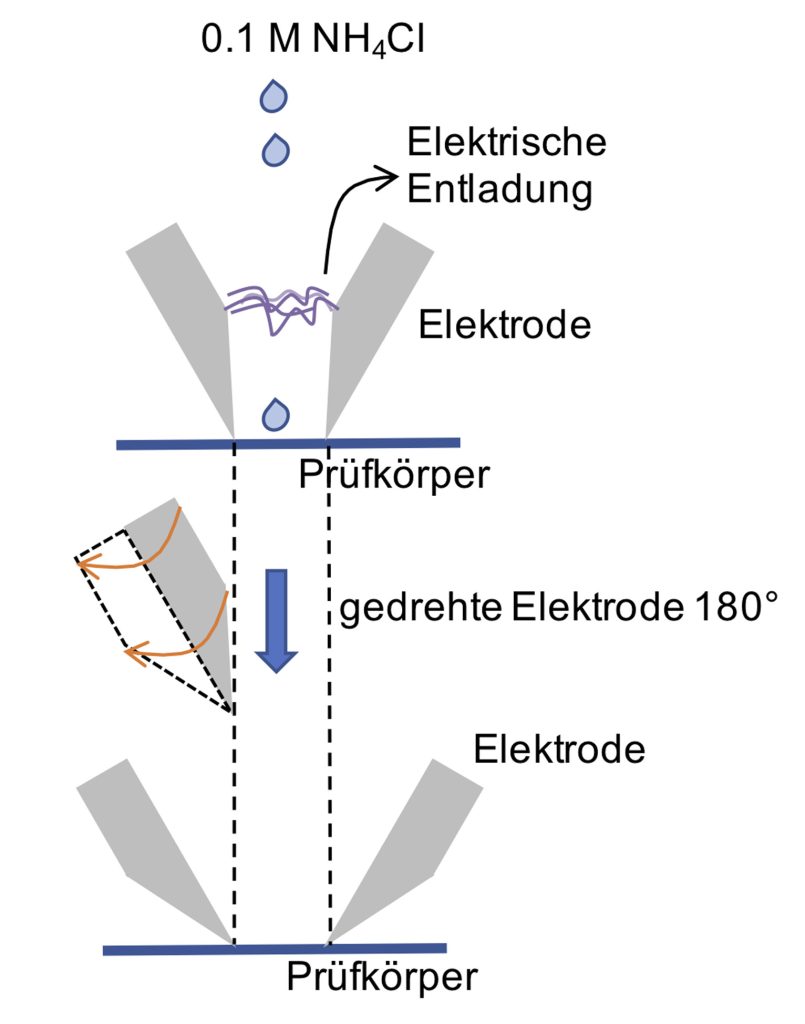

CTI index: electric arc discharges in the air prevent measurement at over 600 V

To measure tracking resistance using the CTI index, two platinum electrodes are positioned 4 millimetres apart on a conditioned test specimen. 50 droplets of a standardized electrolyte solution are dropped onto the electrodes under voltage at 30-second intervals. According to the method defined in IEC standard 60112, the damp test specimen fails the insulating test the leakage current exceeds 0.5 Amperes (A). In its test series on Genestar™PA9T, Kuraray’s research team observed that the narrow gap between the electrodes caused premature arc discharges at higher voltages. This suggests that the current leakage is caused by arcing, rather than the conductivity of the material.

Tracking resistance of up to 925 V: Genestar™ PA9T for lighter weight electric cars

To avoid such premature discharges, the researchers rotated the platinum electrodes by 180 degrees (see diagram/Photo 3). “With this modified test setup, our research team was able to measure tracking resistance at up to 1,000 V,” explains Andreas Weinmann. “Our colleagues tested the modified method on various grades of our polyamide and repeated the tests many times. The tests showed that the halogen-free polymer type GP2300s with 30% glass fibres has excellent tracking resistance. Current leakage only exceeded 0.5 A at a voltage of 925 V.” Thanks to its extremely high tracking resistance, this particularly robust, heat-resistant polyamide from Kuraray can reduce the creepage between electrical conductors, allowing the manufacture of far smaller and lighter connectors for high-voltage applications such as battery and drive technologies for electric vehicles.

Encouraging dialogue in the industry on measuring tracking resistance

The trials provided another finding: the orientation of the glass fibres in the test specimen has a significant influence of tracking resistance. The more uniformly they are oriented in a single direction, the lower the tracking resistance. “Many of the factors affecting the results obtained have not yet been clarified and the modified test setup does not currently meet the requirements of the CTI index,” says Andreas Weinmann. “We want our trials to inject impetus into the industry. The CTI index no longer meets the demands made, for example, by the automotive industry. Our results are an important step towards establishing a new method of measuring creepage at higher voltages. Thanks to dialogue with industry representatives, we have already received a good deal of constructive feedback and many suggestions for optimisation, which we will be integrating into further trials.”