SEPTON™ Q-series – Optimum protection for sensitive fibre optics

Self-driving cars, smart factories and new communication technologies: the 5G standard paves the way for innovations. Fibre optic cables play a central role in this. As the underground link between radio masts and base stations, they facilitate extremely high data rates and in modern vehicles they connect, for example, sensors and electronic control units. A robust casing is needed to give these sensitive cable assemblies lasting protection in tough conditions. The new high-performance elastomers in the SEPTON™ Q-series from Kuraray provide all-round protection for optical fibres. Moreover, they are much lighter and more robust that TPU and TPC.

Casings for fibre optic cables have to withstand many things. If they are laid underground, they are constantly exposed to moisture and need especially good impact and abrasion-resistance. After all, the earth is constantly in motion

Robin Conrad, Marketing & CRM at Kuraray

“In other applications, for example, in cable conduits and vehicles, they are exposed to high temperatures and high humidity. The high-performance materials in our SEPTON™ Q-series give sensitive fibre optic assemblies optimum protection in all conditions. These materials have very good insulating properties, ensuring permanently reliable and stable data transmission.” The SEPTON™ Q-series is a range of high-performance thermoplastic elastomers that combines outstanding softness and elasticity. Compounds with SEPTON™ Q-series products as the base polymer have excellent mechanical properties and are lighter than conventional materials.

The lightweight alternative engineering TPEs

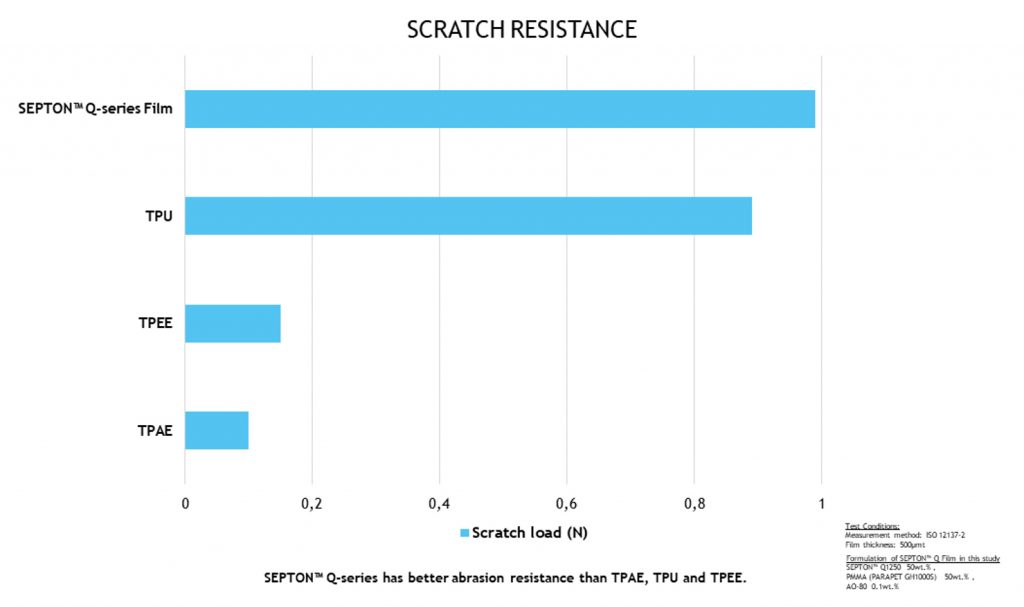

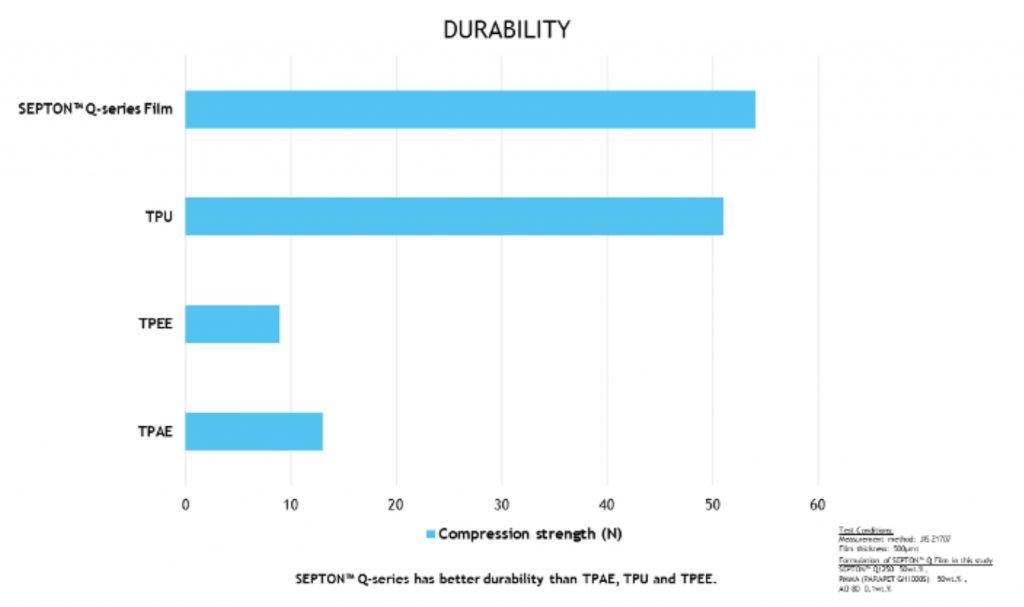

“Our materials have considerably lower density than other engineering TPEs such as thermoplastic polyurethane (TPU) and thermoplastic polyester elastomers (TPC),” says Marcel Gruendken, Manager MD&TS. “Where every gram matters, for example, in the automotive industry and technical applications, the very low weight of the products in the SEPTON™ Q-series has enormous benefits. At the same time, their scratch and abrasion resistance are superior to conventional TPE materials.” Furthermore, users benefit from improved weather resistance. Cable casings made with the SEPTON™ Q-series retain their properties at both very low and warm temperatures. They also exhibit optimum elasticity in permanent use in warm water, steam and tropical climates.

Excellent mechanical properties and many processing options

The SEPTON™ Q-series is highly suitable for use in co-extrusion and film extrusion processes. In addition, it can be combined effectively with polymethylmethacrylate (PMMA). Compounds of these two materials have an exceptionally fine and uniform structure and an extremely good performance profile. The energy return of films made from a compound of SEPTON™ Q-series and PMMA is almost three times higher than comparable TPU films, so they have far higher elasticity. The materials perform better – in some cases far better – than conventional materials in both the Erichsen scratch test and the pinhole test (see photos 2 and 3). And there is another benefit: the SEPTON™ Q-series has far better adhesion to polyolefins than other engineering elastomers. Therefore, these materials are particularly suitable for over-moulding applications, for example, for housings and casings in the electronics industry.

“The products in our SEPTON™ Q-series enable us to offer industrial users a high-performance alternative to conventional TPEs,” explains Marcel Gruendken, Manager MD&TS. “The SEPTON™ Q-series is ideal for many applications in the electrical and electronics industry because the materials can be combined with polymers such as PMMA and polyolefins. And thanks to its excellent mechanical and electrical properties, the SEPTON™ Q-series is suitable for the production of exceptionally high-durability fibre optic cables – to ensure the successful rollout of the 5G network.”